English

- Wrecker Truck

- Fire Truck

- Ambulance

- Aerial Working Platform Truck

- Emergency Rescue Vehicle

- Prison Van

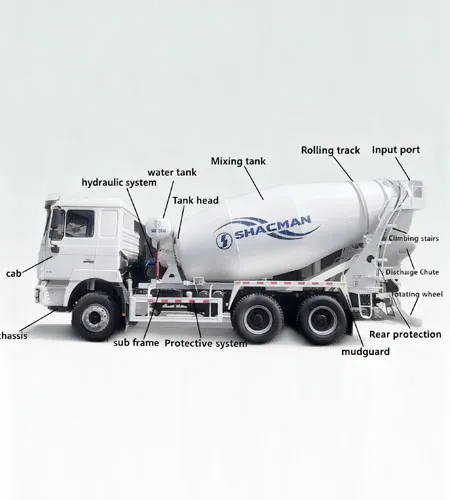

- Concrete Mixer Truck

- Bulk Cement Truck

- Truck with Crane

- Tipper Truck

- Cargo Truck

- Semi Trailer

- Tractor

What are you looking for?